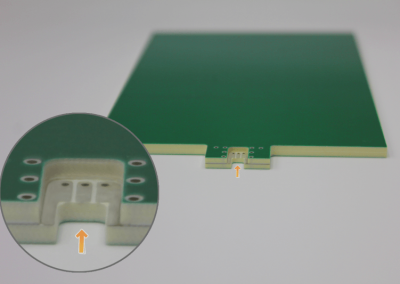

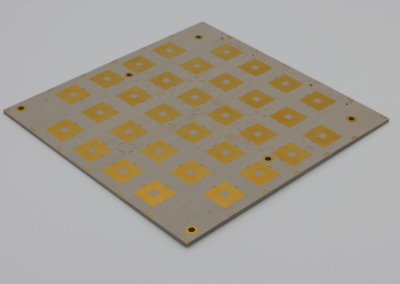

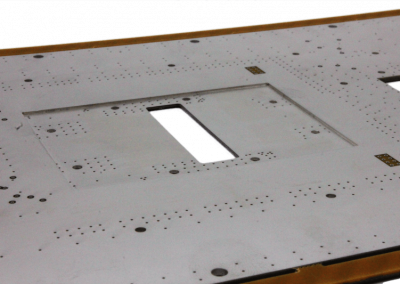

MULTILAYER PCB’S

You are here: Home / Product & Services / Multilayer PCB’s

We can build your high layer count PCB’s using a wide variety of high speed low loss materials from epoxies to PTFE. We impedance model and verify your design during our DFM process. Our In-Process inspection points ensure that our manufacturing processes are within control limits and our final inspection includes micro-section and electrical testing validation ensuring that your design meets your expectations. Let us assist you on your next design requirement!

MECHANICAL CAPABILITIES:

- Standard Panel Size: 12” X 18” & 18” X 24”

- Minimum Line & Space: .004/.004

- Minimum Hole Diameter: .008

- Plated Hole Size Tolerance: +/-.003

- NPTH Size Tolerance: +/-.001

- Plating Aspect Ratio: 10:1

- Positional Accuracy: +/-.003

- Minimum Core Thickness: .001

- Maximum Board Thickness: .350

- Thickness Tolerance: +/-10%

- Soldermask Registration Tolerance: +/-.003

- Minimum Soldermask Clearance: .003

- Legend Registration: +/-.003

- Minimum Legend Feature: .004

- Routing Tolerance: +/-.005

- Minimum Radius: .006

OTHER CAPABILITIES

ONLINE QUOTE FORM

Fastest Custom Quote

Fill out our secure quote form with what you’d like to order – type, size, quantity, location, and desired turn time. We’ll get back to you promptly.

QUOTE VIA PHONE

Most Detailed Quote

Please call to discuss your requirements with one of our skilled Customer Service Representatives.

EMAIL RFQ

Traditional Request for Quote

Please attach your Design files to an email and send to your Advanced Circuitry International Salesperson or Customer Service Representative. Include in your Request for Quote (RFQ) the quantities and turn time desired.